Manual diffusion testing

The Phoenix DB-6 (six-cell diffusion block) offers an ideal platform compliant with 21 CFR Part 11. It supports release-rate testing of six vertical diffusion cells simultaneously using manual sampling method. Controlled by an advanced computerized display, the DB-6 provides uniform and precise heating and stirring of six cells. Its compact footprint saves valuable bench space.

Features of the manual diffusion testing system

Rapid and precise heating

Heating of the receptor media is provided by the DB-6 dry heat block, which is programmable from 25 °C to 45 °C. It has a stated accuracy of ± 1.0 °C, with typical performance within ± 0.3 °C. The dry heat design eliminates the need for conventional water pumps, jacketed cells, and extensive tubing networks.

As a result, the DB-6 heats up quickly. Starting at room temperature, the block and its six diffusion cells typically reach the desired temperature within 30 minutes.

Powerful mixing and homogenization

One key advantage of the Phoenix DB-6 is how quickly it homogenizes the contents of the receptor cell.

Uniformity of the receptor media is crucial in diffusion cell testing for IVRT and IVPT. If a concentrated amount of API remains unmixed beneath the membrane, it can slow down diffusion and compromise the accuracy of the results.

However, the Phoenix system addresses this issue with custom-designed mixer-inserts in each cell, driven by powerful brushless motors. Grooved mixers combined with strong magnetic drives prevent the formation of diffusion-rate barriers from forming directly under the membrane. This reduces variability of test results. Stirring speeds are programmable from 200 rpm to 900 rpm with an accuracy ± 10%.

Bubble detection and removal

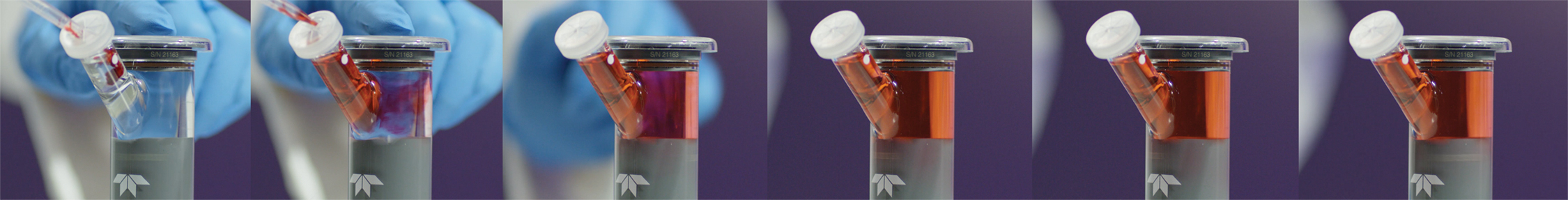

An air bubble trapped beneath the membrane in a vertical diffusion cell can cause variability in release rates. In the Phoenix system, detecting and removing bubbles is quick and simple. Bubbles can be easily spotted using a lighted mirror. Once found, the analyst just lifts and tilts the cell to let the bubble escape through the top of the sampling arm.

Phoenix Diffusion Cells

Le Phoenix™ Diffusion Cell provides improved ease of use, high durability, and greater versatility as compared to conventional hand-blown vertical diffusion cells. Phoenix cells operate on dry heat, eliminating the need for water-jacketing.

This allows construction from heavy-duty borosilicate glass held to very tight dimensional tolerances. The extract-and-replace sampling through the large diameter opening in the sampling arm accommodates standard pipette tips (~300 μL). This simplifies the sampling process while reducing training and operating costs.

Phoenix DB-6 21 CFR Part 11 compliance

Support for 21 CFR Part 11 compliance includes:

- A self-calibrating speed control

- Built-in diagnostics with instant on-screen alert

- Auditable logs for events, errors, test reports, test history, and service

- Serial number tracking of eight different elements (six of each element)

- Real-time clock

- Serial printer connection

- Security settings for up to 50 users or administrator profiles

- Inactivity timeouts

- Incorrect login lockout

Configurate your own system

Our partner Teledyne Labs has an unique configurator, try it out here, or just contact us, to configurate your system with one of our specialists.

Transition to automation