Ideal system for pilot scale crystallization and filtration

AGI Pilot Plant Filter Reactor PLUS meets the demands of crystallization processes by combining the functionality of a reactor and a filter in a single system. The entire crystallization workflow, including crystal formation, filtration, product washing, and drying, can be completed without ever opening the vessel.

The Pilot Plant Filter Reactor PLUS handles large quantities of crystalline product safely and efficiently, making it ideal for process development, kilo lab work, and pilot-scale production.

- Reaction, filtration and washing in one vessel

- Contamination-free material processing

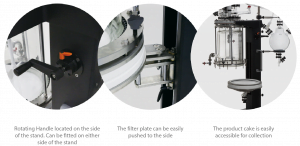

- Vessel swing/rotating mechanism for easy product collection

Features of Pilot Plant Filter Reactor PLUS

- Reaction and Filtration in a single vessel

- Easy access to filter by using a lever mechanism

- Design that safeguards against product loss

- Easy cleaning and maintenance

- Scale-up to 100 L

- Space, time, and cost saving

- Wide process temperature range: -90 ℃ to +200 ℃

- Support structure with castors for mobility

- Vessel with fully jacket design for maximized thermal transfer efficiency

Excellent performance and functionality

The AGI Pilot Plant Reactor PLUS combines top-tier performance, functionality, and ease of use. Ring baffle technology, optimized vessel geometry, and wall thickness ensure high performance, while the flexible stand enhances overall usability.

The reactor’s quick and easy vessel displacement lets you spend more time on your process and less on setup. Offering outstanding value, the system is available with 10 L, 20 L, and 30 L vessel capacities.

Recover end product with absolute ease

General specifications of the Pilot Plant Filter Reactor PLUS

| Vessel capacity | 10 L, 20 L and 30 L |

| Vessel type | Double wall, full jacket |

| Filtration area | 317.3 cm² (10 L), 514.7 cm² (20 L), 711.6 cm² (30 L) |

| Operating pressure | Full vacuum to atmospheric pressure |

| Operating jacket pressure | Up to +0.5 barG (0.05 MPa) |

| Operating temperature | -90 °C to +200 °C |

| ΔT – Thermal shock resistance | 110 °C (double wall) |

Note:

Overhead stirrer, circulator and chiller are not included

Wetted parts: Borosilicate Glass 3.3, PTFE, FFKM, PFA