Microwave Synthesizer

The Discover® 2.0 is a microwave synthesizer. It is the leading microwave reactor for performing any organic or inorganic chemistry.

It is the industry’s most advanced system for microwave-assisted chemical synthesis, designed for organic and inorganic chemistry applications. This device features a high-quality 300 mL single-mode microwave reactor and easy-to-use software.

The 10″ touchscreen lets you program a reaction in seconds. You can get the best synthetic yield in just minutes.

Features of the microwave synthesizer:

- Widest pressurized vessel sizes for a single-mode microwave – 10mL, 35mL, 100mL

- IR Temperature Sensor that sees through glass and Teflon® (iWave®)

- Vent and reseal technology for safe handling of over-pressurization (ActiVent)

- Variable speed magnetic stirring and rapid compressed air cooling

- Integrated camera to observe your reaction

- Upgrade options: Autosamplers – 12/48 positions; Gaseous Addition, Sub-ambient temperature, Flow cells

The best approach for Chemical Synthesis

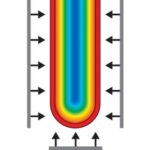

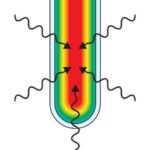

Microwave synthesis offers unique heating ad0vantages for synthetic chemistry. Reactions are heated volumetrically, directly, and instantaneously, making the process faster and more efficient than other heating methods.

These microwave features provide organic chemists with better product yields and greater control over reaction conditions, ensuring precise results in materials and inorganic chemistry. Microwave energy has become the industry standard for medicinal chemistry, nanomaterials synthesis, and academic teaching labs due to these clear advantages.

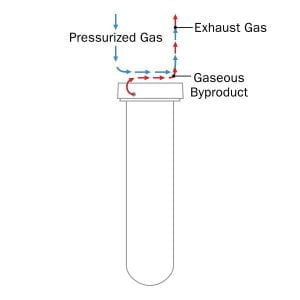

Activent: Safe, Pressurized Reactions

It automatically vents gas by-products safely through exhaust tubing at the back of the system as they form during the reaction.

This significantly reduces vial failures, allowing reactions to reach higher temperatures, and requires only an easy-to-use snap-on cap, no crimping tools needed.